HIGH THROUGHPUT IN NARROW AISLES

The Linde A man-down turret truck embodies a high throughput rate in particularly narrow aisles. This is achieved by a modern drive train that even at maximum lift heights can achieve high-speed lifting and travel. In addition, the forklift can travel and lift at the same time. Just as important are the residual lift capacity, and various camera and assistance systems. They assist with such things as navigation in the warehouse, accident prevention or facilitating rapid handling at high levels. The VNA truck A is of modular construction. The customer can choose from different motors, batteries, lift masts, chassis and many other features to meet his operating requirements.

Characteristics

Safety

Three point operation protects the driver: Hand sensors on the steering wheel and lift button, as well as a dead-man’s switch installed in the foot-well or in the seat, must be operated simultaneously in order to move the truck. In addition, a service technician can program travel, lift and lowering end stops. Available as supplementary equipment, the aisle safety assistant detects barcodes, or RFID transmitter-marked unevenness, obstacles in the shelving or on the ceiling, and adjusts the driving and lifting speed, lift height or forks extension accordingly. Optional sensors on the front and rear detect whether persons or objects are in the line of travel, and stop the truck.

- Three point operation

- Pre-adjustable travel, lift and lowering end stops.

- Optional personnel protection system

Ergonomics

The driver operates the lift axis easily with an ergonomically shaped, multi-axis lever. Traveling comfort is provided by the large cab, the highly adjustable seat and the intuitive arrangement of the control elements. The sideways seat position gives the driver a good view in all directions and avoids strenuous body movements. A soft, non-slip floor mat and an optional air cushioned seat reduce the shock and vibration transmitted to the driver.

- Multi-axis control levers

- Highly adjustable seat

- Cab with storage capacity

Handling

Even at extreme lift heights, the drive technology of the Linde A man-down turret truck can achieve high speeds. In addition, there are several assistants and camera systems for handling at high levels – for example, the automated forks cycle. At the press of a button, the truck carries out three movements during pallet emplacement or removal. Using RFID technology, the truck can be incorporated into a comprehensive warehouse navigation system. This enables the driver to find the desired pallet location quickly, or truck functions are controlled according to location. Dependent upon the requirement, the forklift can be equipped with swivel reach forks or telescopic forks.

- Good residual lift capacity

- Modern assistance systems

- Numerous positioning aids

- Electronic support functions

Service

Overall, the robust and long-life technology of the A turret truck achieves reduced service and life-cycle costs. The CAN bus connection ensures a simple service process: All truck data can be read and checked by notebook. Battery replacement is achieved quickly, using a change trolley or removal rack.

- CAN bus connection

- Quicker battery replacement

- Robust truck construction

Videos & Images

Technical Data

| Model | Load capacity/Load | Battery voltage/rated capacity (5h) | Lift | End aisle width, with/without load | Travel speed, with/without load |

| A Example 1 | 1.0 (t) | 48 / 700 (V)/(Ah) | 4600 (mm) | 3346 (mm) | 10.5 / 10.5 (km/h) |

| A Example 2 | 1.35 (t) | 48 / 980 (V)/(Ah) | 5200 (mm) | 3490 (mm) | 10.5 / 10.5 (km/h) |

| A-Example 3 | 1.35 (t) | 48 / 1120 (V)/(Ah) | 5050 (mm) | 3694 (mm) | 10.5 / 10.5 (km/h) |

Optional Equipment

-

BlueSpot™

-

Aisle safety assistant

-

Warehouse navigation

-

Fleet Management

-

Linde System Control (LSC)

-

Cold storage protection

BlueSpot™

Lane warning device Linde BlueSpot™ Enhances safety during operation as the LED spot makes the forklift noiselessly visible.

Aisle safety assistant

The assistance system uses barcodes or RFID tags in the aisle to detect unevenness in the floor, as well as obstacles in the shelving or on the ceiling and restricts truck functions, such as speed, lift height or forks extension at these specific locations.

Warehouse navigation

The forklift receives movement tasks via the warehouse management system. The system detects the location in the warehouse, as well as the current lift height and guides it independently to the pallet location. The driver only has to operate the movement function.

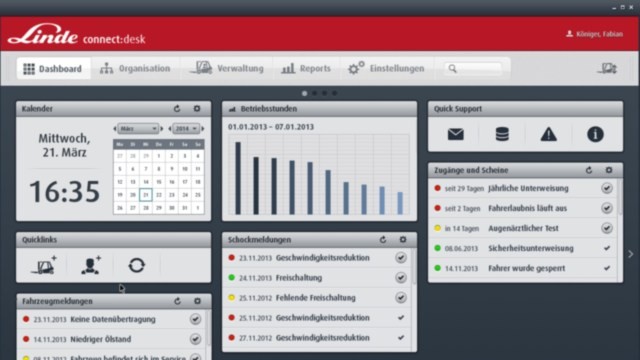

Fleet Management

How and by whom are the individual forklifts used? What do the usage data of the forklifts look like, and is each one roadworthy? Using a combination of software and hardware, the connect: fleet management system provides the appropriate answers

Linde System Control (LSC)

The system provides improved throughput rates and enhanced safety. The LSC Standard basic version indicates to the driver the residual lift capacity dependent upon the lift height. Enhanced LSC versions adapt additional lift and/or travel speed automatically to the weight of the load being transported.

Cold storage protection

Amongst other things, the forklifts are operated with special hydraulic fluid, lubricants and corrosion proof coating and there is the option to choose from several enclosed, insulated cabs.