Very narrow aisle trucks K-modular

THE COMBINATION FORKLIFT FOR NARROW AISLES

WORK EFFECTIVELY AND WITH A VIEW IN THE HIGH SHELVING

The K man-up turret truck from Linde Material Handling enables high turnaround capacity for order picking and handling processes in high rack warehouses. The powerful drive trains make this possible, as the truck can move and lift at the same time. Also, even at high lift levels the speed remains high and a high level of residual lift capacity is available. Various assistance systems are available which help to navigate accurately through warehouse or to avoid obstacles. Not least, Linde System Control improves the process: Depending on the version, the system adjusts the lift and travel speed according to the weight being transported. There are various versions of the mast, chassis, battery and cab for the very narrow aisle trucks, which can be combined according to usage requirements. There are around 10 million possible truck configurations.

Characteristics

Safety

The driver must make contact with three points, otherwise they will be unable to move the combination forklift: the hand sensors on the control panel as well as the dead-man’s switch on the cab floor. This prevents incorrect operation which may lead to accidents. For the safety of the driver, there are also electrically monitored side cabinets which must be closed when the platform height is above 1.2 meters. The optional personnel protection system continuously scans the aisle and stops the truck if people are in the vicinity. For additional safety, an optional Aisle Safety Assistant detects RFID-tagged or barcode-marked unevenness, obstacles in the shelving, on the floor or on the ceiling and automatically limits the speed, lift height or fork extension at these locations. Service technicians can program general travel, lift and lowering end stops in the truck system, which can be adjusted. The standard, load and weight variants within the 'Linde System Control' assistance system assist the driver by adjusting speed and optimizing driving behavior depending on the lifting height, load recognition and load weight.

- Three-point operation

- Electrically monitored side cabinets

- Aisle Safety Assistant

- Pre-adjustable travel, lift and lowering end stops.

- Optional personnel protection system

- Linde System Control (Standard, Load, Weight)

- Dynamic Reach Control

- Rescue Alarm

Ergonomics

The new control panel has an ergonomic design. In addition, its position can be adjusted across three axes – for example to aid comfortable working in both a standing and sitting position. The driver can also adjust the height and incline of the folding seat. The color display of the control panel shows all the important information such as the time, speed, lifting height and steering angle at a glance. To make work easier, several storage options are available in the large, draft-protected cab. The chassis and the cab are decoupled from each other so that less shock is transmitted to the driver. Tilting side barriers are also available as an option. They swing outwards if the driver leans on them. This decreases the driver's distance from the shelving and makes order picking easier for the operator.

- The control panel’s height, incline, and angle can be adjusted

- Split control panel for whole-pallet handling, particularly in a sitting position

- Large cabin with the best view of lifting and loading

- The height, incline and angle of the seat are individually adjustable

- Storage options available

- Option for a tilt barrier

- Knee cushion for comfortable order picking

Handling

Even at high lift levels, the modern drive train technology of the combination forklift can achieve a high speed. In addition, the high residual lift capacity as well as modern RFID assistance systems enable navigation in the warehouse and handling on the shelving to be carried out more quickly. When using the Linde connect: fleet management system, it is also possible to optimize the whole usage cycle of the trucks. Additional support for handling is provided by functions such as the automatic lift height pre-selection and the automatic forks cycle. In this process, the truck automatically carries out three movements during pallet placement or removal at the press of a button. In the new version of the K truck, the main and auxiliary lifts can be raised or lowered simultaneously. This allows the driver to reach high-bays in a single step without having to operate the main and auxiliary lifts successively. The forks can also be put into position considerably more quickly through simultaneous control and can be controlled very easily at a convenient height. The energy generated by braking and lowering the load is restored to the battery. This improves usage duration and cost-effectiveness equally.

- High speed at high lift levels

- Modern assistance systems

- Several positioning aids

Service

The robust technology of the Linde K combination forklift ensures low service costs and a long service life. Its CAN bus connection enables technical problems to be rapidly diagnosed and rectified using a notebook. Like the three-phase motors for lift and movement, both of the independent braking systems are maintenance-free. With the battery carriage frame, which is available as an option, lateral battery changing is completed rapidly.

- CAN bus connection

- Low-wear braking system

- Fast battery replacement

Videos & Images

Technical Data

| Model | Load capacity/Load | Battery voltage/rated capacity (5h) | Lift | End aisle width, with/without load | Travel speed, with/without load |

| K-Example 1.1 | 1.1 (t) | 80 / 620 (V)/(Ah) | 7200 (mm) | 3808 (mm) | 12 / 12 (km/h) |

| K-Example 1.5 | 1.5 (t) | 80 / 775 (V)/(Ah) | 11800 (mm) | 4042 (mm) | 12 / 12 (km/h) |

Optional Equipment

-

Active Stability Control (ASC)

-

Operating Panels

-

Attachment Bars

-

BlueSpot™

-

Aisle Safety Assistant (ASA)

-

Warehouse Navigation

-

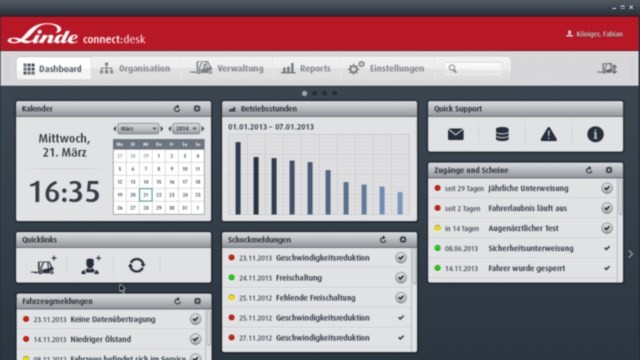

Fleet Management

-

Linde System Control (LSC)

-

Modular Truck Design

-

Tilting Barriers

-

Mirror Module

-

Cold Storage Protection

Active Stability Control (ASC)

The Intelligent Assistance System Active Stability Control is an intelligent assistance system that detects unevenness between the left and right sides of the aisle and automatically compensates for shocks and vibrations so that the truck can achieve its maximum handling performance even on less than optimal floors.

Operating Panels

For the cab, the customer can choose between a front or divided operating panel. Both variants can be adjusted quickly for working in a standing or sitting position. The integrated full-color display provides the driver with all the relevant information at a glance, from the speed of the forklift and the lifting height to the steering angle and the time of day.

Attachment Bars

The driver cab can be enhanced with several individual fittings, such as monitor, terminal scanner, storage facilities and writing support.

BlueSpot™

Lane warning device Linde BlueSpot™ Enhances safety during operation as the LED spot makes the forklift noiselessly visible.

Aisle Safety Assistant (ASA)

The assistance system detects barcodes or RFID tags in the aisle which mark unevenness in the floor, as well as obstacles in the shelving or on the ceiling, and restricts truck functions such as lift or driving speed, lift height or fork extension at these specific locations.

Warehouse Navigation

The forklift receives driving tasks via the customer's warehouse management system. Using barcodes or RFID tags, the system determines the location in the aisle and measures the current lift height. Based on this information, it guides the truck automatically to the desired location. The driver only has to operate the drive function.

Fleet Management

How and by whom are the individual forklifts used? What does the usage data of the forklifts look like, and is every single truck fit to drive? Using a combination of software and hardware, connect: provides the appropriate answers.

Linde System Control (LSC)

The system provides improved throughput rates and enhanced safety. The LSC Standard basic version indicates to the driver the residual lift capacity for the particular lift height. Enhanced LSC versions adapt additional lift and/or travel speed to the weight of the load being transported.

Modular Truck Design

The forklift can be adapted in various ways: There are various motors, batteries, lift masts and chassis available. Linde can also individually configure the driver’s cab with different seat variants and storage facilities. This enables more than 10 million configuration variations.

Tilting Barriers

If the driver leans on the barrier, it tilts outwards by 10 cm. This enables the driver to reach the racking better, making order picking easier.

Mirror Module

The equipment package includes a large rear-view mirror as well as lateral working lights to illuminate the working surroundings in the racking. There is also an optional ventilation system available to cool the driver when working at high lift levels in hot weather.

Cold Storage Protection

The K-truck is available for cold store application. Amongst other things, the forklifts are operated with special hydraulic fluid and lubricants and receive a corrosion proof coating. Additionally, there is the option to choose from a variety of enclosed, insulated cabs. A closed and heated cold store cabin provides comfortable working conditions.

Qet a Quote