EFFECTIVE ORDER PICKING AT VARIOUS LEVELS

The N20 Vi/VLi low-lift order picker with lifting operator platform improves productivity while picking orders – primarily at ground level, but also at a working height of up to 2.8 meters. The operator benefits from the design concept, as the operator's platform and forks are positioned behind the battery. The design reduces the number of movements required during order picking. As well as the lifting platform, the N20 VLi model also features an additional lift which the operator can use to bring pallets up to a convenient working height, cutting down on strain when positioning goods. The optional compartment area in front of the steering unit, which rises with the platform, is an additional picking aid. The truck boasts a load capacity of up to two tons, and 1.2 tonnes for the additional lift.

Characteristics

Safety

The design of the platform and control unit ensures that the operator always remains within the confines of the truck, which enhances safety while driving and picking. The upward-slanting outer edge helps the driver to avoid missteps, for example when the platform is raised. Additionally, the N20 VLi model features a polycarbonate screen between the platform and lifting mast, protecting the operator against dangerous contact with the lifting mast. When cornering, the truck automatically reduces its speed. The entire platform functions as a deadman's switch. If the operator leaves the platform or presses the emergency stop, the truck will automatically brake at a rate determined by the load.

- Platform for stability

- Polycarbonate screen in front of the lifting mast

- Angled platform edge

- Reduced speed while cornering

- Load-proportional emergency brake

Ergonomics

The low yet broad entry makes access easier for the driver, while also providing sufficient space for picking from the platform. The platform has suspension and dampens vibrations. The multiple compartment areas serve as additional working aids, as do the power-steering and ergonomically designed grips, which allow the driver to reach all of the controls easily. The N20 VLi model can also be equipped with an additional lift, enabling the operator to raise pallets to working height for loading, alleviating back strain.

- Low entry height

- Foot mat for better cushioning

- Central steering control with all control elements

- Additional lift for N20 VLi model

Handling

For effective commissioning processes at different levels, the N20 Vi/VLi trucks are equipped with a driver's platform which can be precisely raised and lowered. The truck can lift and drive simultaneously, allowing the operator to reach the required goods quickly. Lowering the platform is conveniently controlled via a foot switch. Using their 3 kW three-phase motors, the order pickers can reach a top speed of ten kilometers per hour, with or without a load. Both model variants possess an initial lift, allowing them to traverse ramps and uneven surfaces easily.

- Linde Load Control for the platform's lift functions

- Simultaneous driving and lifting

- Power steering

- Foot switch for lowering the platform

- Self-centering steering

Service

All of the truck's technical parameters can be read out via CAN bus and then analyzed on a service laptop, where they can be adjusted accordingly. The technician can also access all central components directly simply by removing a service cover to the front. The three-phase technology is protected against dust and moisture, and is therefore maintenance-free. Lateral battery changing can be carried out safely and simply using a roller conveyor.

- Truck data readouts via CAN bus connection

- Maintenance-free three-phase motor

- Central components easily accessible

- Rapid battery replacement

Technical Data

| Model | Load capacity/Load | Battery voltage/rated capacity (5h) | Turning radius | Travel speed, with/without load |

| N 20 VI | 2.0 (t) | 24 / 375 (V)/(Ah) | 2491 (mm) | 10 / 10 (km/h) |

| N 20 VLI | 2.0 (t) | 24 / 375 (V)/(Ah) | 2470 (mm) | 10 / 10 (km/h) |

Optional Equipment

-

Storage Compartment

-

Fleet Management

-

Order picker pack

-

Walk alongside button

-

Accident monitoring

-

Access control

Storage Compartment

The large compartment towards the front, which raises alongside the platform, can carry goods with a total weight of up to 50 kg.

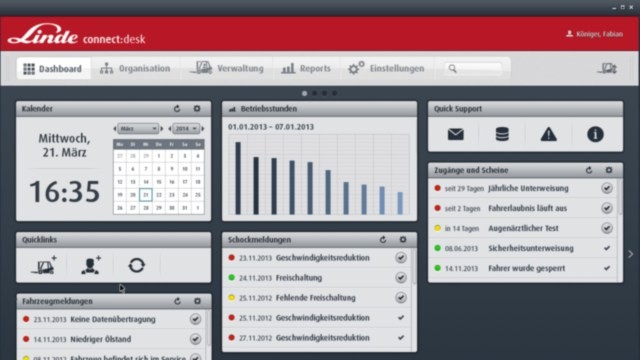

Fleet Management

Linde's connect: fleet management solution supports the operator in the optimization of truck utilization and service planning, among other things.

Order picker pack

The pack includes a rotatable clipboard and another compartment area in the front.

Walk alongside button

Buttons are located on either side of the seat that allow the truck to be moved slowly. These allow the driver to operate the order picker from the outside and comfortably walk alongside the truck to the next picking point.

Accident monitoring

A shock sensor detects vibrations – whether caused by driving errors, uneven surfaces, or improper truck use. Data analysis carried out via the fleet management software provides information about the causes of damage and accidents.

Access control

Access control via the connect: fleet management system ensures that trucks are used only by authorized persons. The driver must identify themselves using a PIN or a RFID card before they can start the truck.

Qet a Quote